Depending on their shapes, tungsten-based alloys can be categorized into tungsten alloy rods, tungsten alloy blocks, tungsten alloy plates, and tungsten alloy spheres. While their physicochemical properties are generally similar, their applications differ.

Taking tungsten alloy rods as an example, also referred to as tungsten bars, they are alloy products with refractory metal tungsten as the hard phase and metals such as cobalt, nickel, iron, or copper as the binding phase, known in English as tungsten bar.

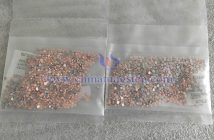

In terms of physicochemical properties, tungsten bars combine the characteristics of tungsten and the binding phase, including high melting point, high density, high hardness, high strength, low thermal expansion coefficient, high elastic modulus, wear resistance, high-temperature resistance, and good electrical and thermal conductivity. Note that the specific physicochemical properties of the alloy depend on the proportion of raw materials. When the binding phase is copper, the alloy’s color shifts toward copper as the copper content increases; with higher copper content, the alloy’s melting point, density, and hardness decrease, while its electrical and thermal conductivity improve.

In terms of production techniques, the manufacturing methods for tungsten alloy rods vary depending on their chemical composition. For instance, tungsten-nickel-iron alloy rods can be produced using powder metallurgy or injection molding techniques. Powder metallurgy involves using metal powders as raw materials, which are shaped and sintered to produce various types of products. Injection molding involves injecting molten colloid into a mold cavity under pressure to create the desired product. Tungsten-copper alloy rods are typically manufactured using the copper infiltration method, where tungsten powder is pressed into shape, sintered to form a porous tungsten skeleton, and then infiltrated with copper through a series of processes.

In terms of applications, tungsten bars are widely used in military, defense, aerospace, aviation, maritime, lighting, and automotive industries. When processed into wires, tungsten bars can serve as filaments, support wires, or lead-in wires. They can also be ground into needles or manufactured into various electrodes, high-speed cutting tools, and sputtering targets.